NP500L

NP Series

X/Y axes : 500 x 300 mm

U/V axes : 120 x 120 mm

Z axis : 310 mm

- Comply with TUV CE comformity, both safety and desired design with easy operation.

Specification

NP500L (Submerged Type)

Max. work piece size

850 x 550 x 300 mm

Wire diameter

0.15 - 0.3 mm

Max. work piece weight

600 kg

Number of axes controlled

XY axis linear motor, UV Z axis AC servo motor

Table travel of X Y

500 x 300 mm

Maximum taper angle

±26°/ 100mm with wide diamond guide and nozzle

U & V axis travel

120 x 120 mm

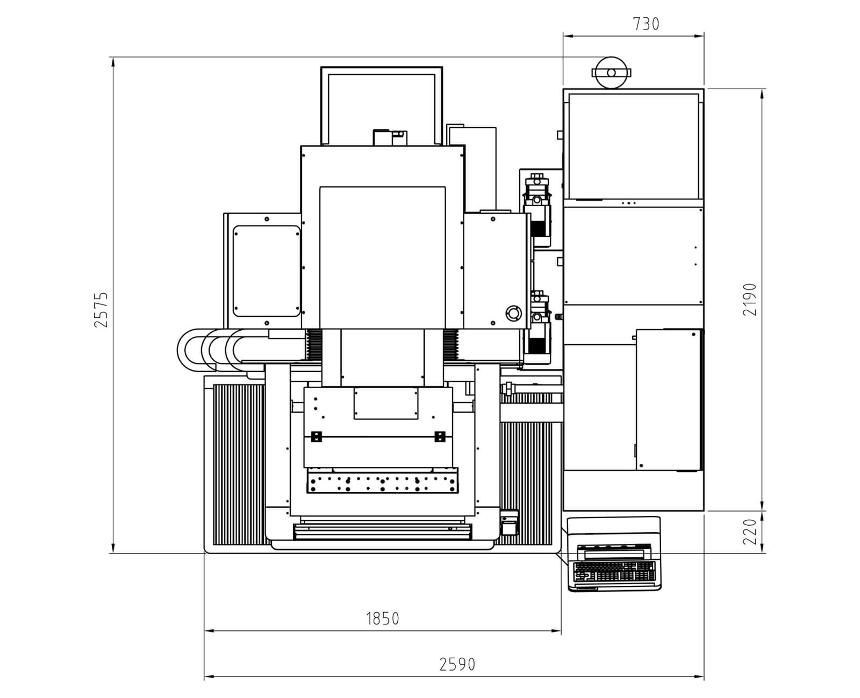

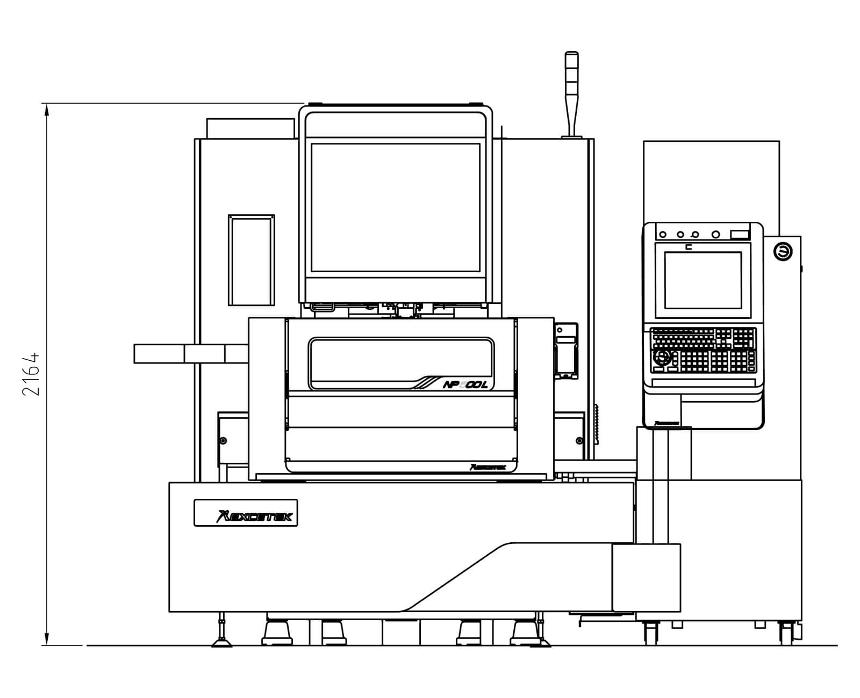

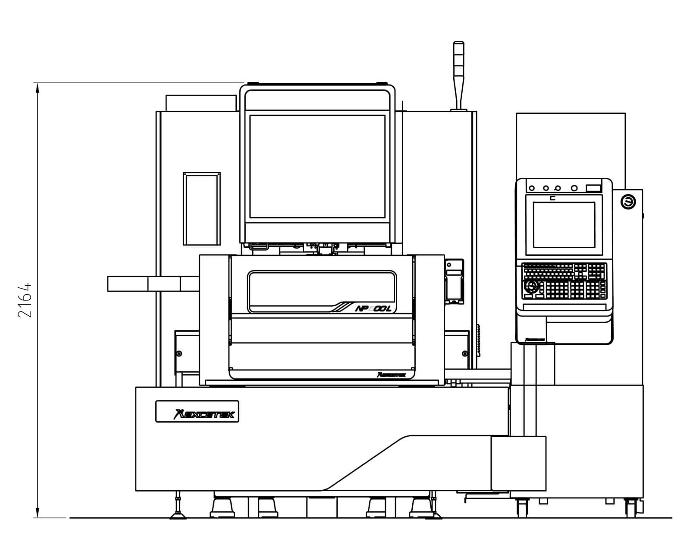

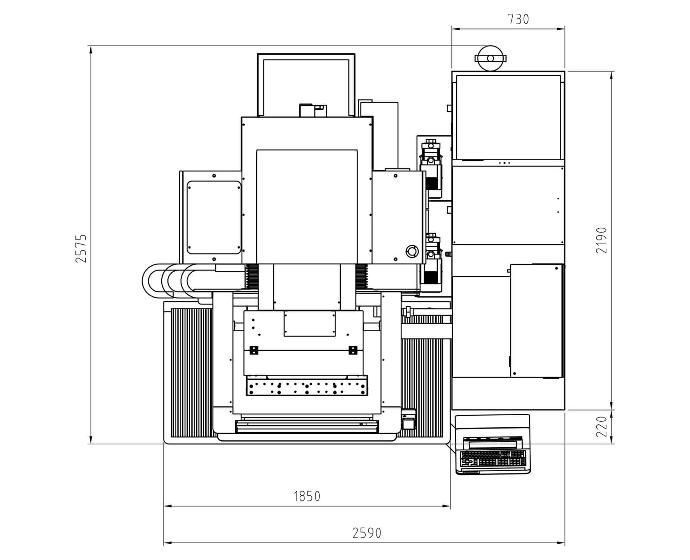

Machine dimensions

2590 x 2575 x 2165 mm

Z axis travel

310 mm

Machine weight

3350 kg

Dielectric Tank

Tank capacity

750 L

Deionzer

auto

Paper filter

2 / pcs

Chiller unit

auto

Features

High Precision

- Smart Corner Control, Stable Discharge processing, Super Finish Circuit (SFC) provide more accuracy.

Efficiency

- DPM module, Precision mark control, Electrolysis Free(EF) generator system.

Cost effective

- Intelligent access control, Reduce Wire Consumption, Economic concerned price.

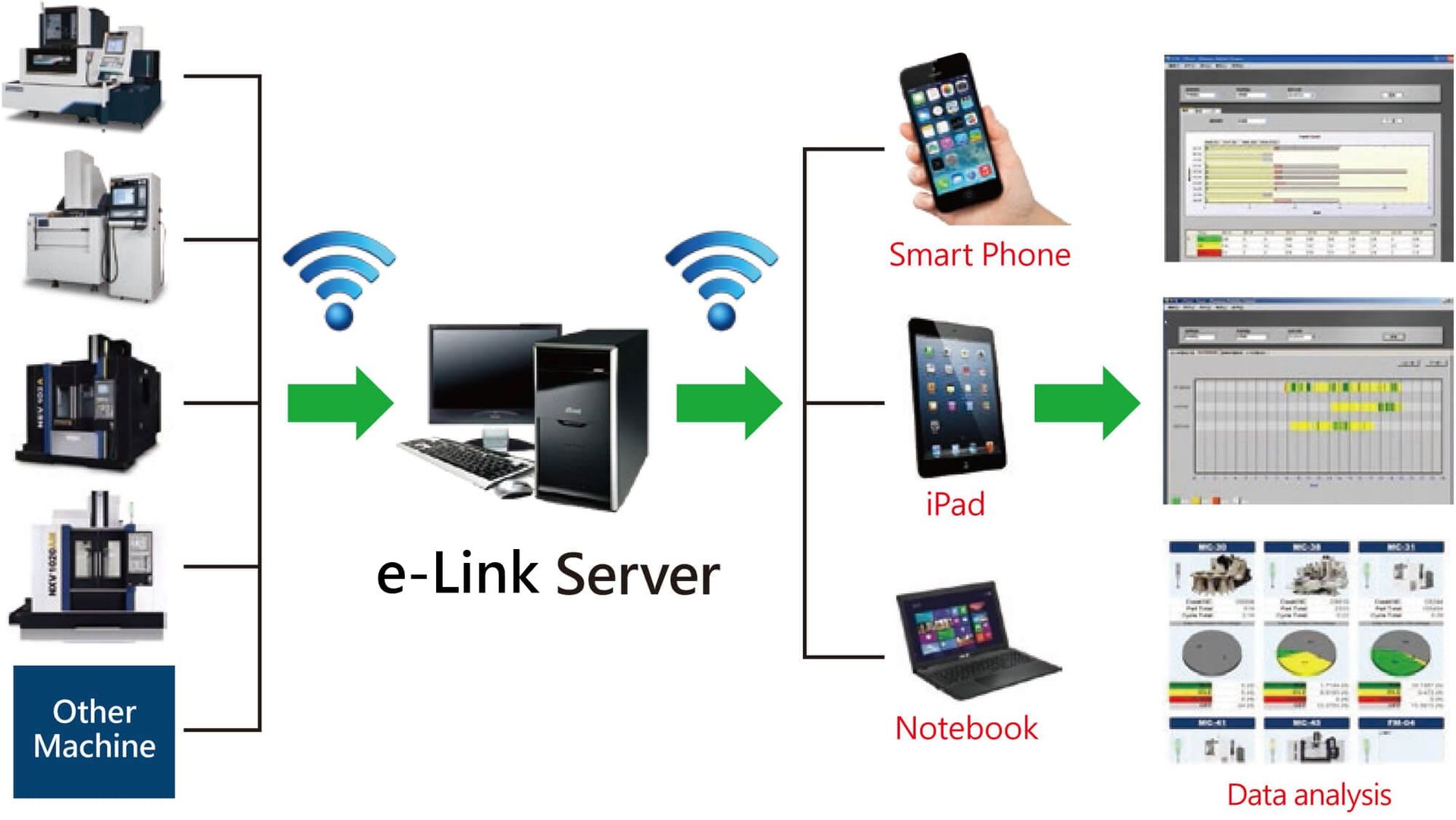

Intelligent Networking

- Remote monitor management, Controller connector, Portable device monitor.

Automation

- High speed Auto Wire Threading, Robo-arm transfer of Workpiece, Probe Auto Measurement and Correction

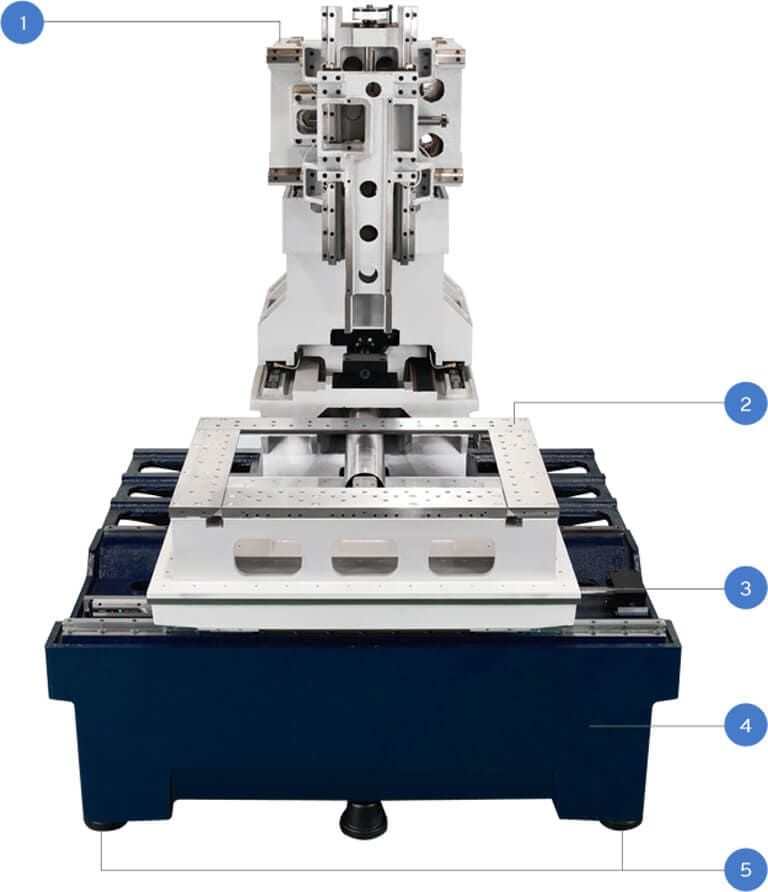

Machine feature

- Rigid U, V truss design

- Stainless steel worktable with hardness HRC 50°.

- Machine Casting is designed based on the FEA analysis for increasing the rigidity.

- Machine base with extra wide.

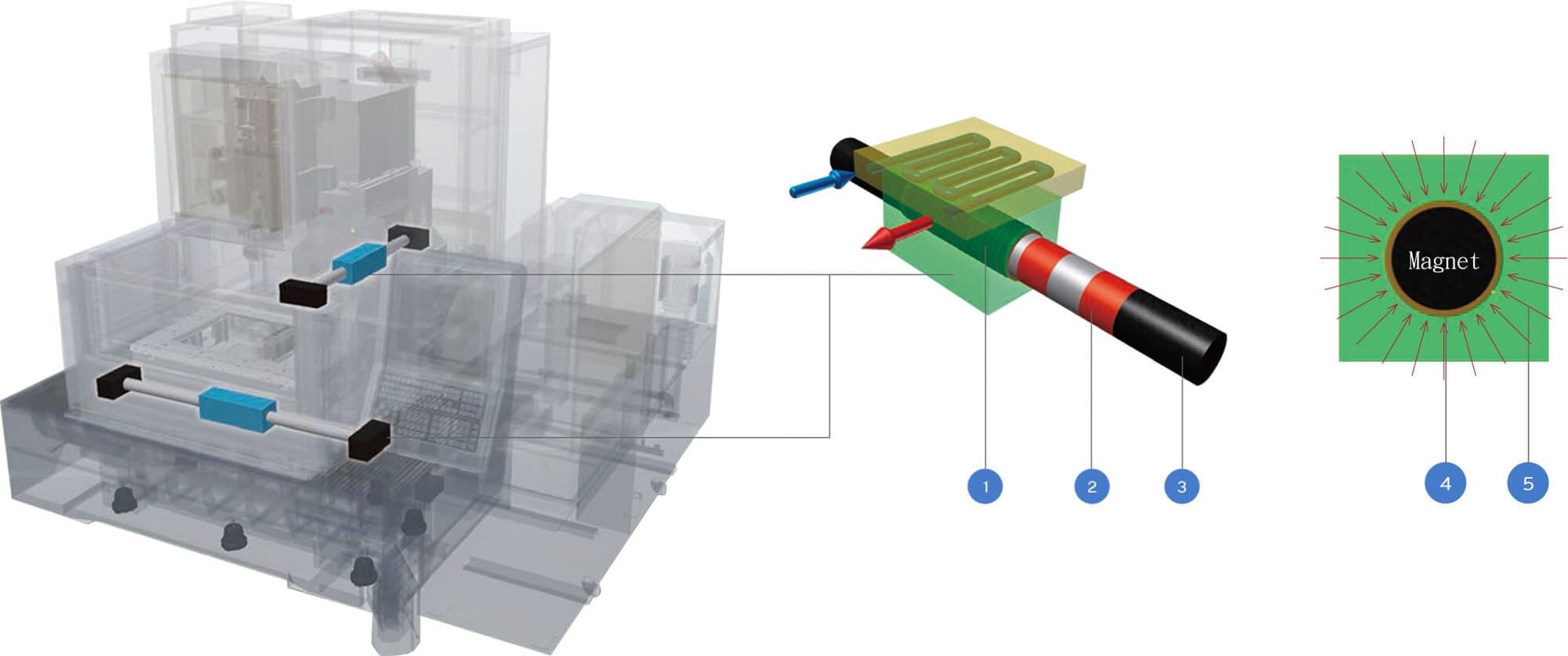

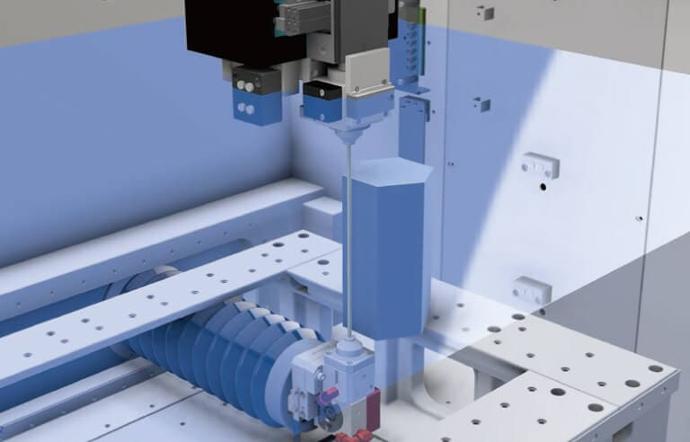

Linear Sheft Motor Driver System

MechanicalStructure

The machine provides the constant temperature for improving the accuracy while machining where the heat generated by the linear motor will affect the accuracy. The water circulation reduces the temperature generated by the linear electric motor from the magnetic field, with high thrust, high efficiency and low energy consumption.

Features such as a 0.1 μm high-resolution digital ruler and controller provide high-precision forming and ultra-fine finishing.

Coil

Magent

Shaft

Coil

Magnetic flux

Improved Operability

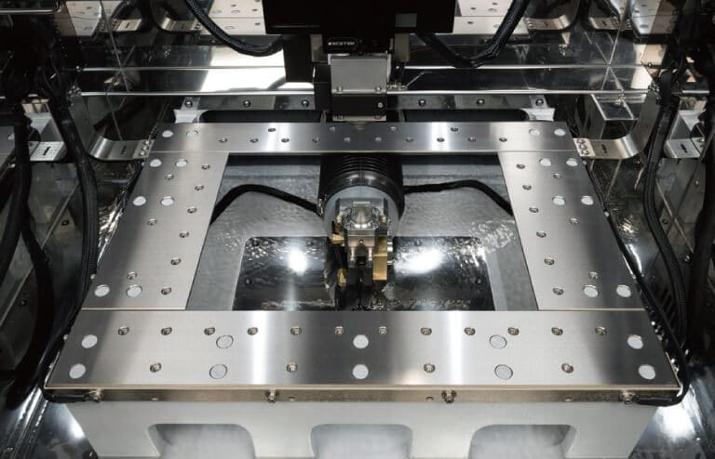

4-side Hardened Stainless Steel Table

- It has certified the standards of TUV Certification for safety and metal desired design.

- Power slider door design to save installation space and light operation

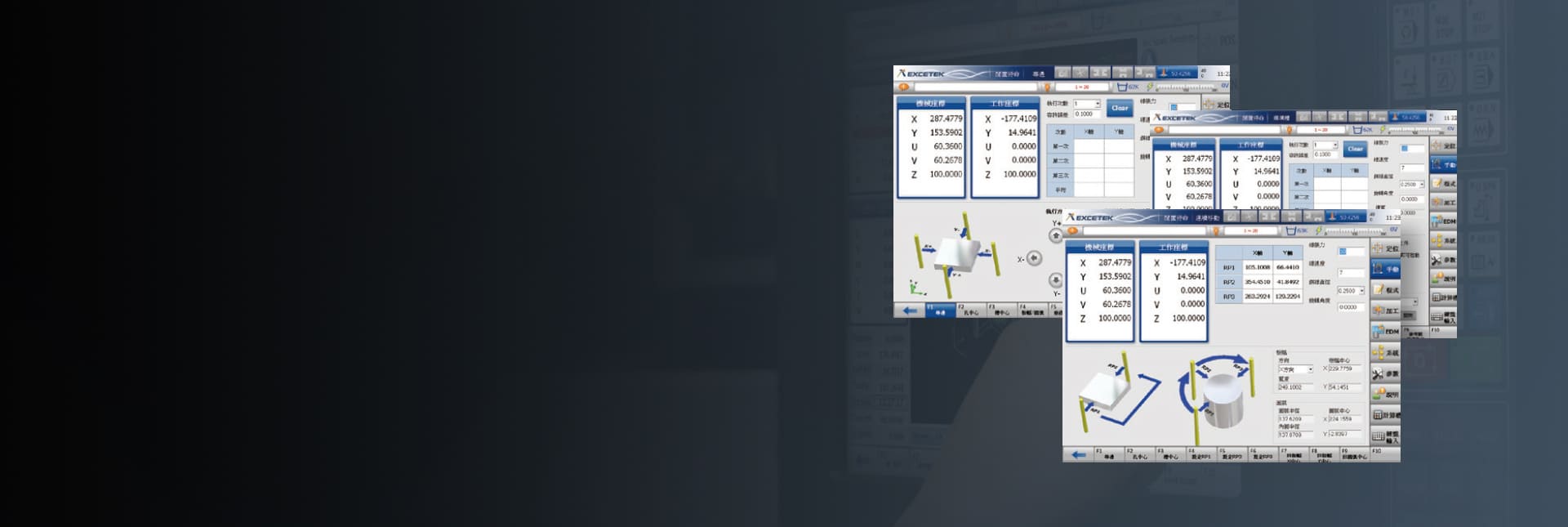

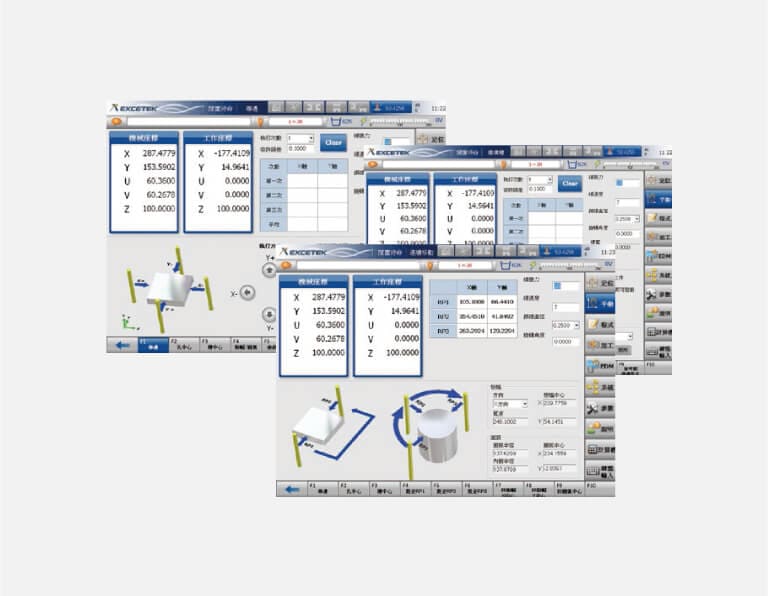

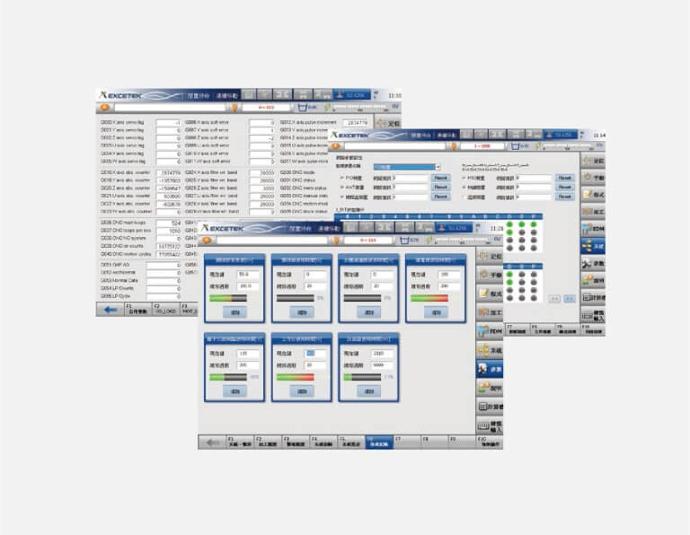

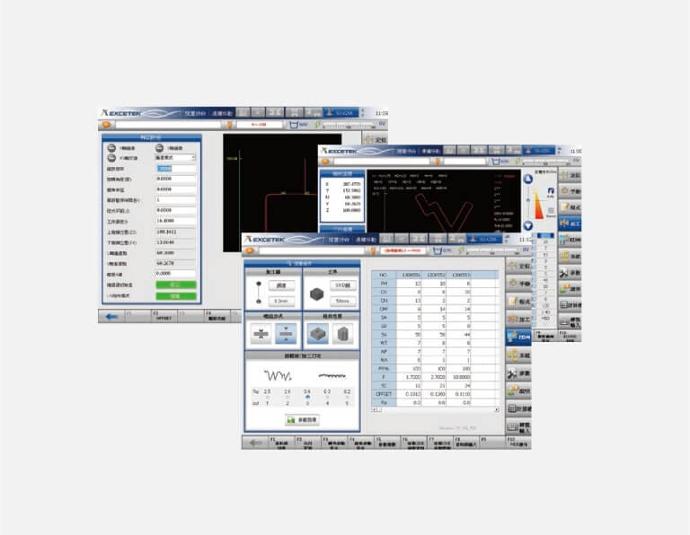

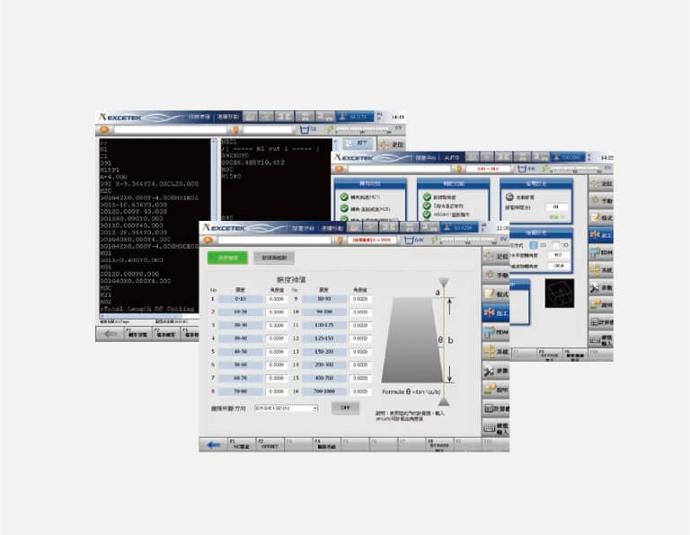

Graphical Interface

The HMI panel is easy to operate, using class leading ergonomic technology

Intelligent Machining mode

Workpiece postioning function

Maintenance and Diagnosis information

Technology data search function

Graphical interface

Useful function

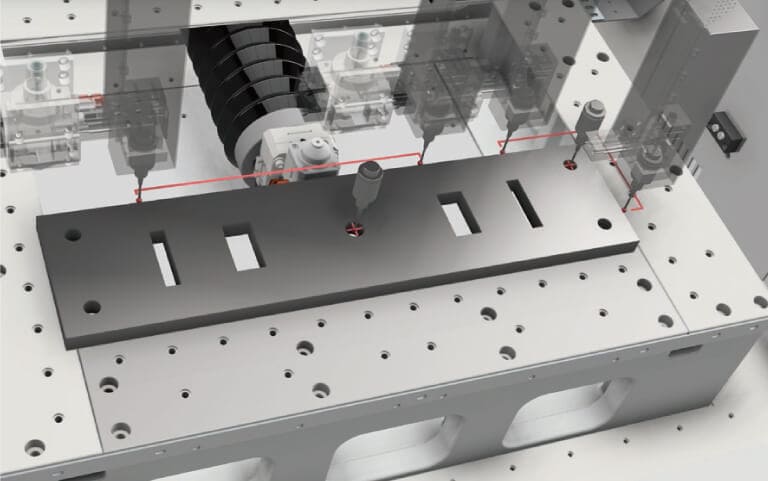

Auto Wire Threading

200mm Submerge threading

200mm Submerge threading

400mm thickness threading in break point

High Speed Auto Wire Threading System

Workpiece thickness 100mm

- Wire annealing and cutting : 10 sec

- Threading : 10 sec

Reliable Auto Wire Threading system

In EXCETEK, AWT provides a sophisticated design which generates continuous unmanned operation for 24 hours. Unlike other systems it can thread from the point of the wire breakage or break point.

A water jet function enables the machine to thread workpieces up to 500mm.

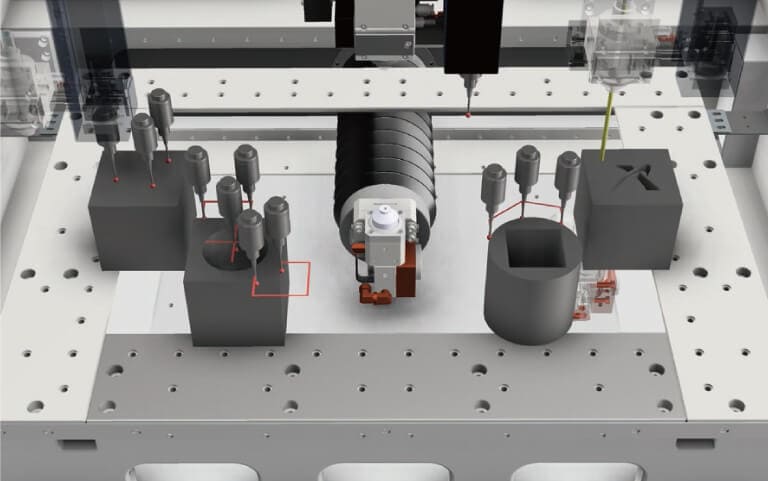

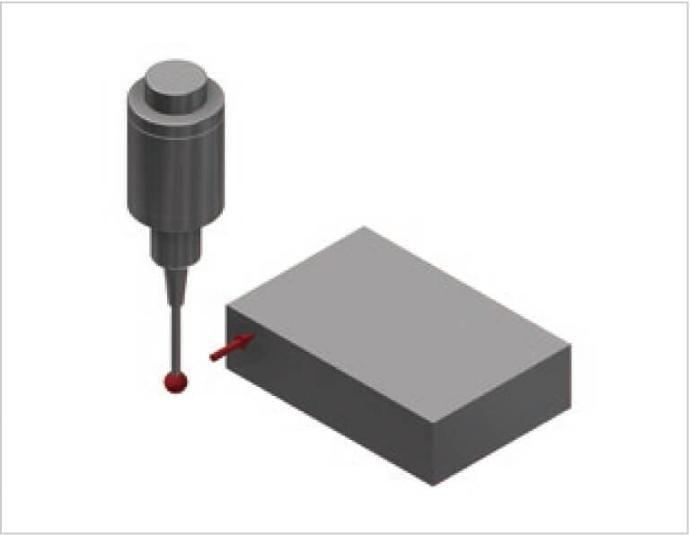

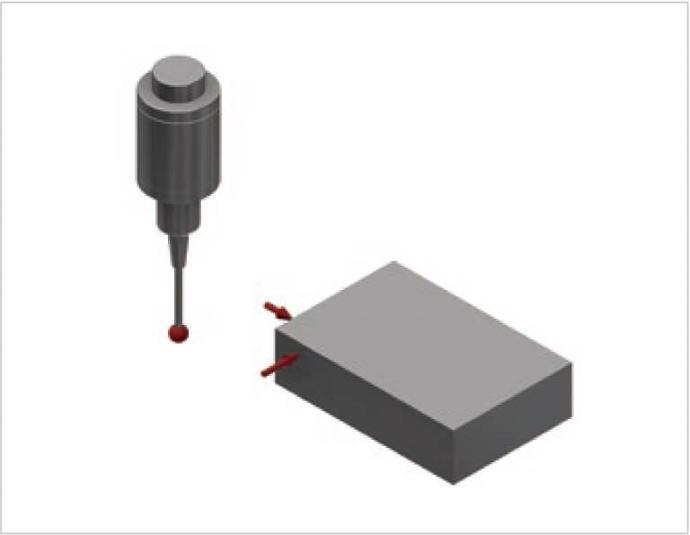

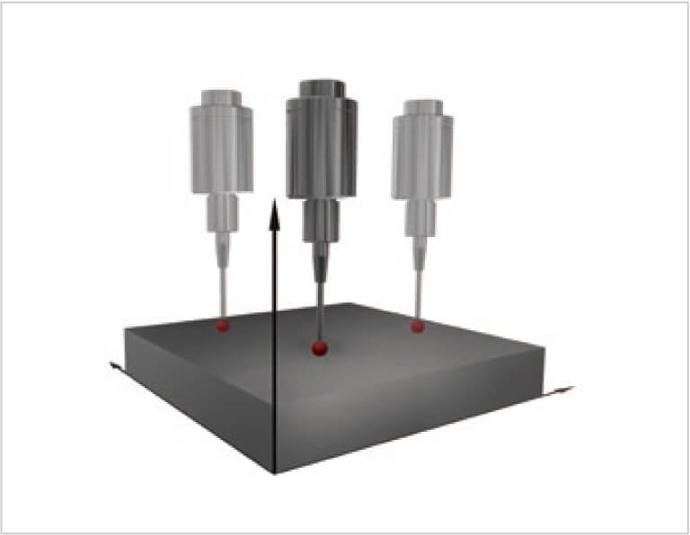

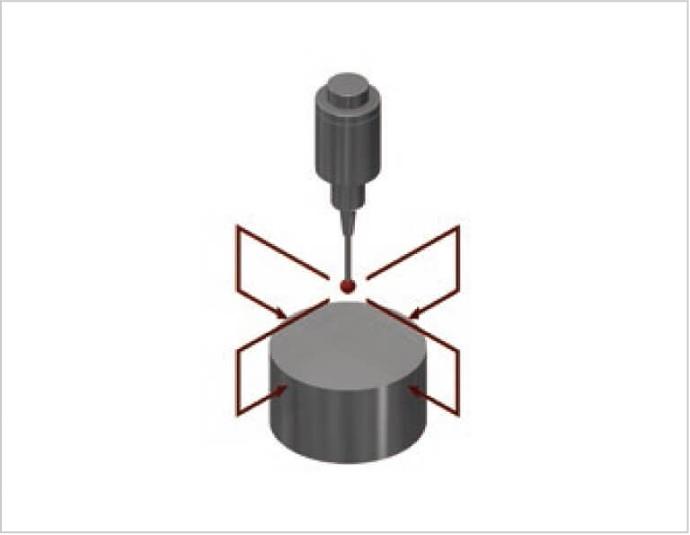

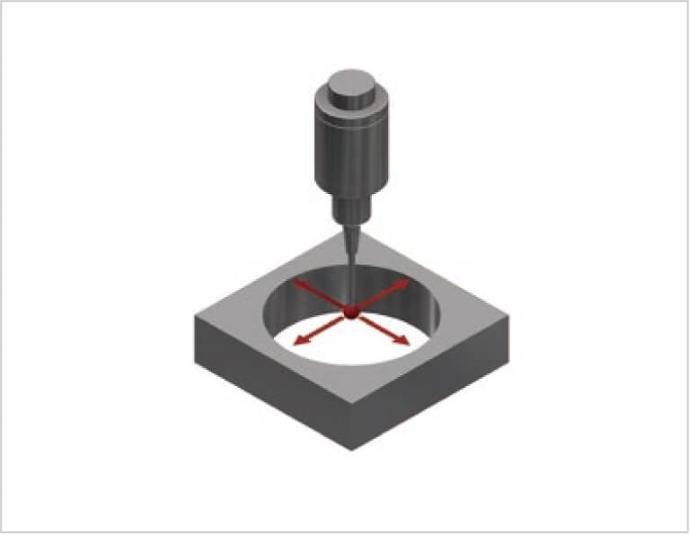

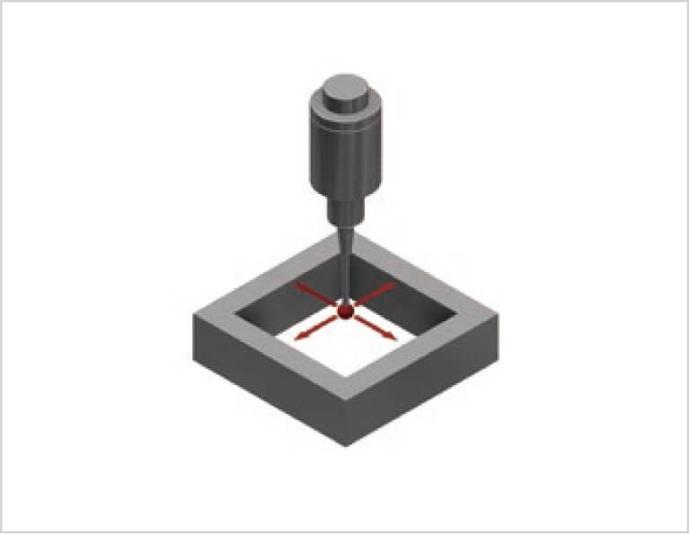

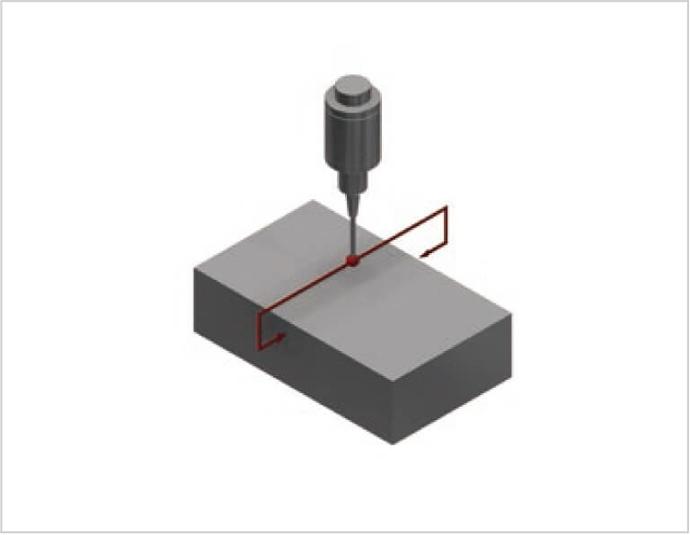

On-line measurement system

CBefore the machining, on-line measurement and calibration instead of the conventional one, significantly reduce the time to calibrate the workpiece. With the macro command the automatic measurement calibrates the reference point; enhance the machining accuracy. After machining, directly on-line measure the workpiece on the table; avoid the unexpected error from dismount/mount the workpiece.

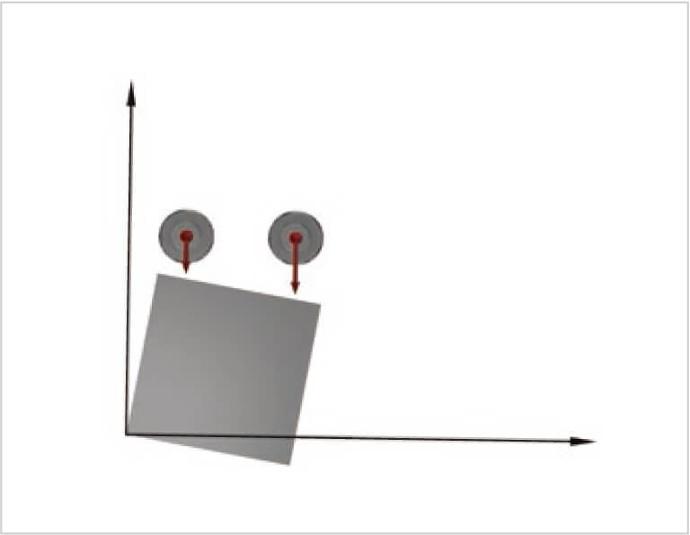

Multi-workpiece machining

Automatic compensating the 3D flatness of workpiece.

Automatic compensating the parallelism of workpiece (AR)

Automatic machining reference point measurement.

Processing AWT automatic wire threading

Go to the next workpiece to continue processing.

Processing automation

Automatic compensating the parallelism of workpiece (AR)

Automatically calibrate the reference point

Processing AWT automatic wire threading

Automatically measure the results after machining

Export the measurement report

Automatic Measurement Application

Cutting Technology

Type

|

Without control |

Using control |

A |

0 |

0 |

B | 0 ~ -2 µm | -8 ~ -10 µm |

C | 0 | 0 |

D | 0 ~ -2 µm | -8 ~ -10 µm |

Using automatic measurement system, you can be able to find the inclination measurement, AR correction and reference point. EXCETEK provide a probe to measure the accuracy and auto-calibrate the precision mold before machining which reduce the pre-processing time.

With macro instruction, it automatically measure and correct the reference point to improve the mold processing accuracy. After processing, the accuracy test is performed directly on the workbench, which saves the repeated disassembly time of the workpiece and avoid the processing errors caused by repeated disassembly.

Compensating the 3D flatness of workpiece automatically.

Compensating the Axis rotation of workpiece (AR) automatically.

Measuring the processing reference point Automatically.

It processes auto wire threading (AWT).

It automatically processes to next workpiece after completion of the working.

Accessory

Standard Accessories

XY axis linear scale

Brass wire x 1 spool

AWT

Clamping tool x 1 set

Ion exchange resin x 10L

Vertical alignment jig x 1 set

Paper filter x 2 pcs

Diamond guide x 2 pcs

Upper and lower flushing nozzle x 2 sets

Energizing plates x 2 pcs

Options

Clamping Beam

W-Axis

AVR 15KVA

Jumbo Feeder L-50A

Transformer 15KVA

Short Message Service (SMS)

Signal Tower

Remote Monitor System

Auto measurement system

Super Finish Circuit