Specification

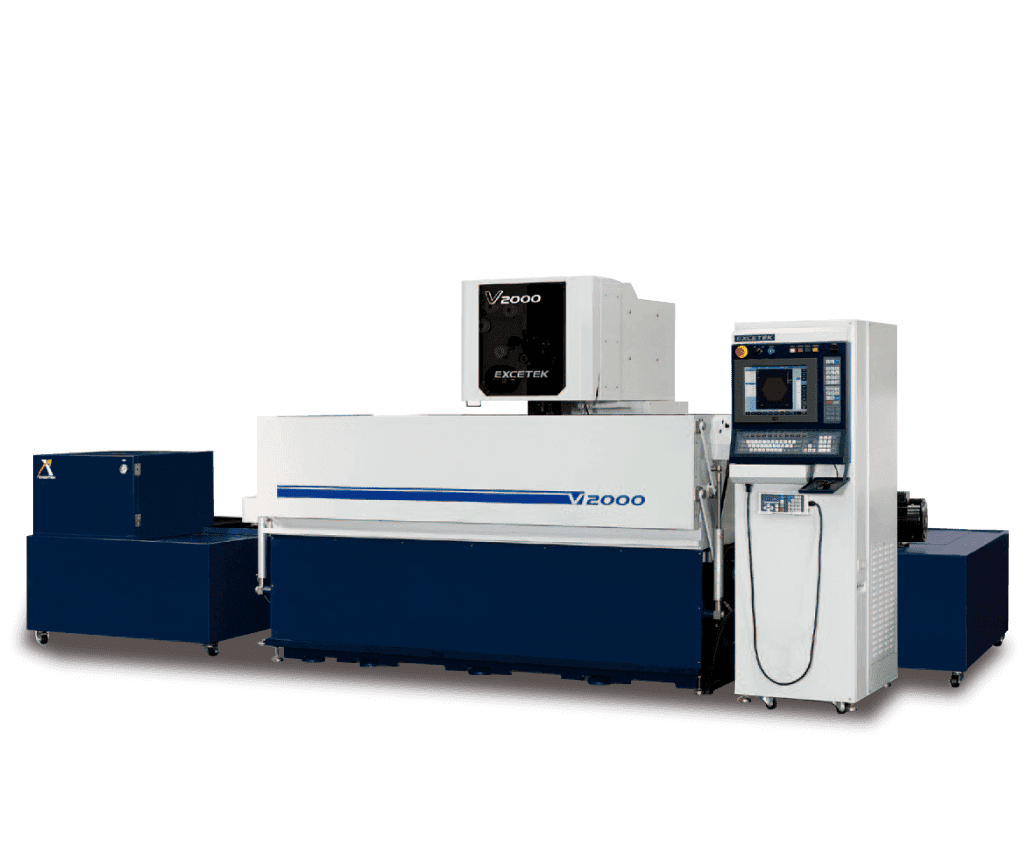

V2000

Max. workpiece size

2400 x 700 x 345 mm

Max. workpiece weight

2500 kg

Travel of X/Y axes

2000 x 450 mm

Travel of U/V axes

160 x 160 mm

Travel of Z axis

350 mm

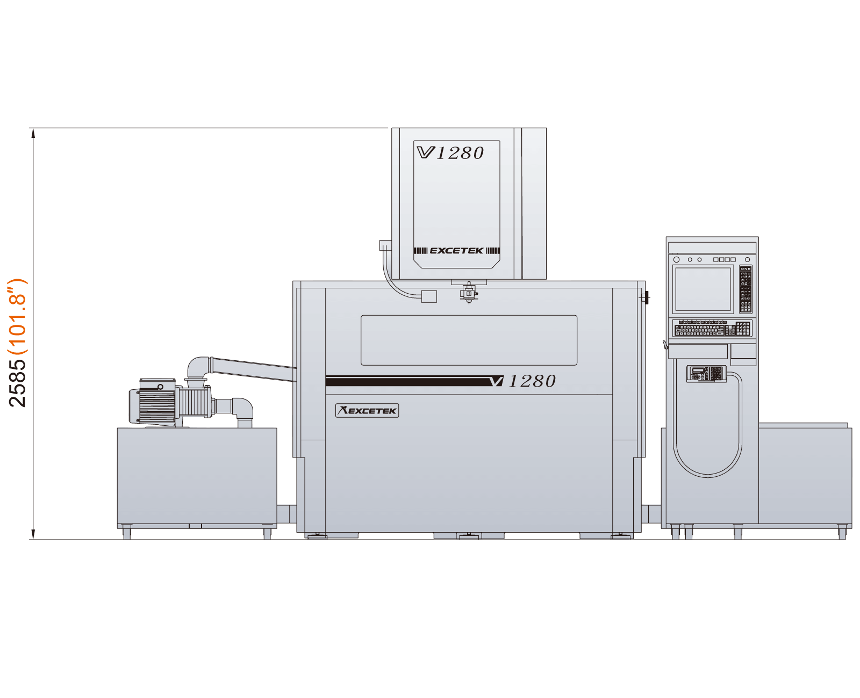

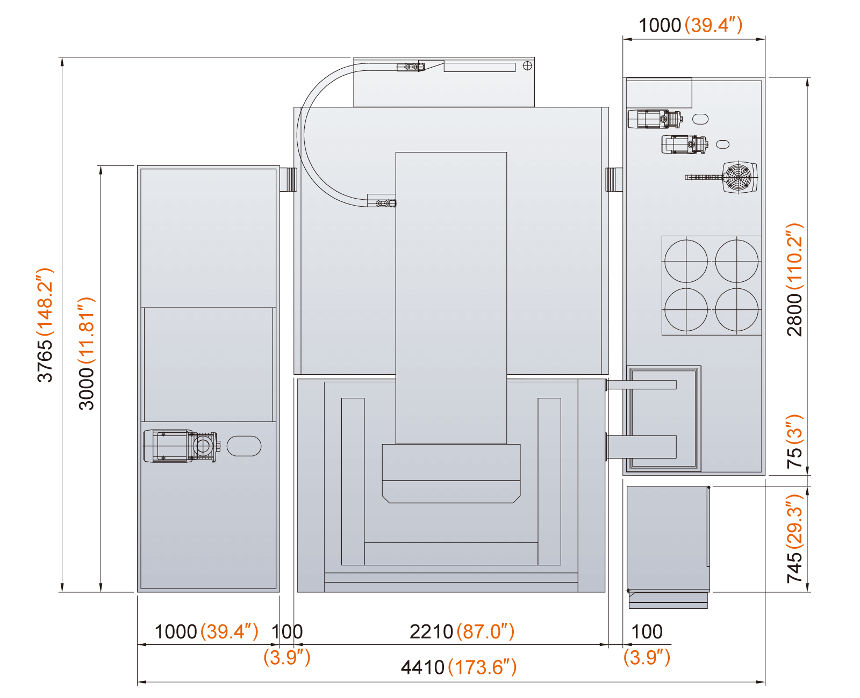

Machine size

5260 x 3135 x 2200 mm

Water tank capacity

2500 L

Features

Machine feature

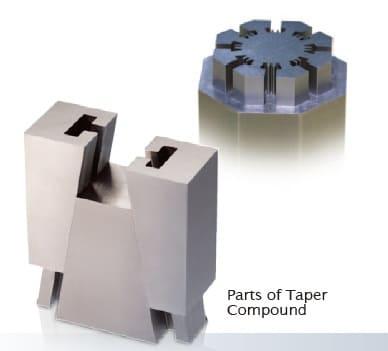

Rigid U, V truss design

Stainless steel worktable with hardness HRC 50°.

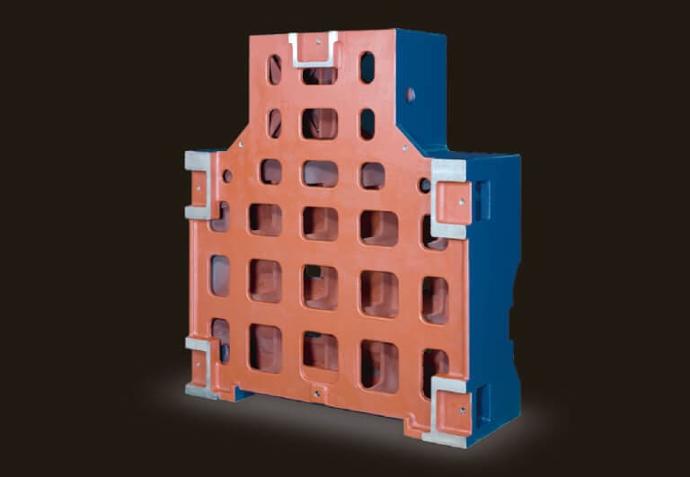

Machine Casting is designed based on the FEA analysis for increasing the rigidity.

Machine base with extra wide.

Water Cooled lower arm prevents thermal expansion caused by heat buildup. Therefore, the accuracy will be improved.

*** To ensure thremal balance, RIB location is designed by finite element analysis (FEA)assuring and optimized rigid structure.

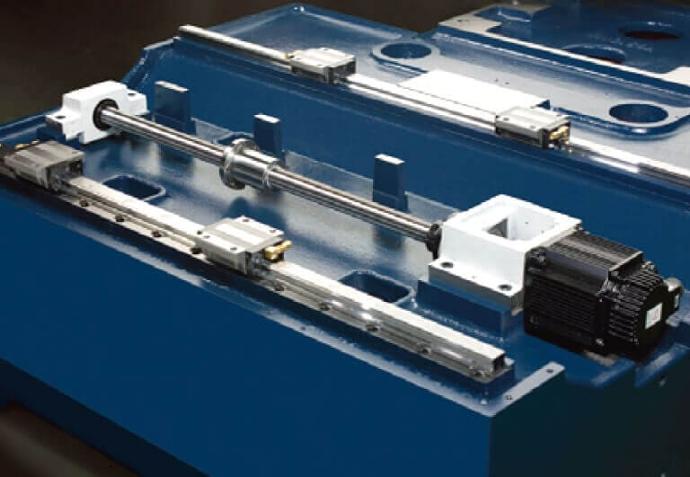

Precision is achieved through Extended distance between linear guide ways; Cryogenic treatment of C1 class ball screw; Supported by two sides and a high resolution AC servomotor. Theses outstanding features boost accuracy in micro step amounts up to 1 µm.

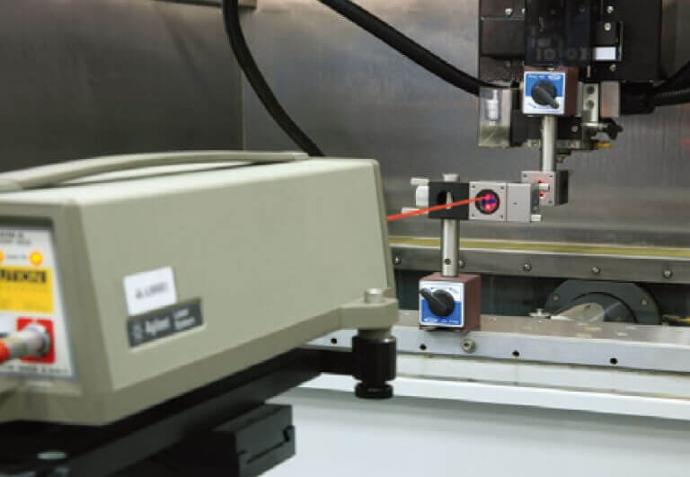

Laser calibration, pitch error compensation.

Closed loop linear scale (Option).

A rugged case iron machine structure is the foundation of precision.

High Frequency Calculating and Pulse Control

- “The embedded system” are used in the machine for reducing the load of the control.

- RS-485 networks are used in the machine to transmit between the module groups.

- CRC functions are used to verify the data which is received are correct or not.

- Adapts ASIC chip to increase the stability of the circuit.

- Watch Dog functions for self-protection.

- Sparking relevant information of real-time feedback makes spark erosion steady.

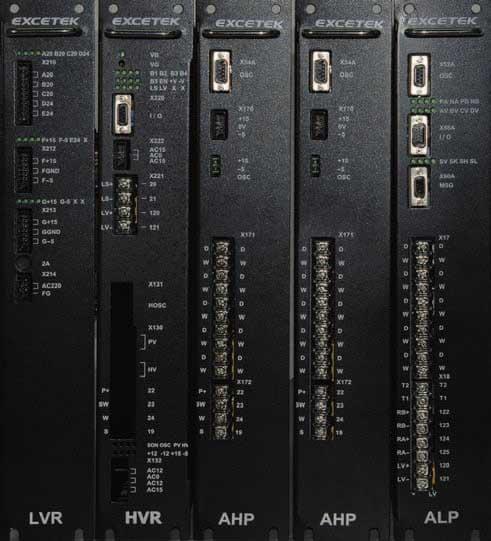

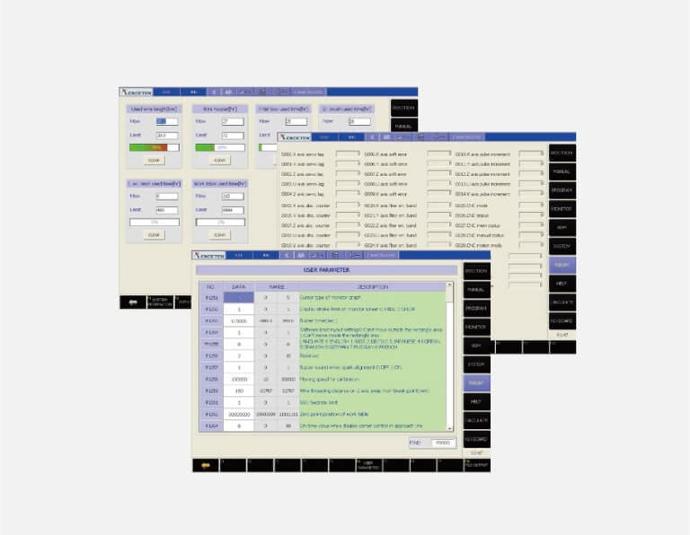

Modular Designed System

An optimal module on the electric circuit PCB of each module I/O gives an LED indication which provides the information of the energy produced by the controller while machining. It also helps easier for user maintenance purposes.

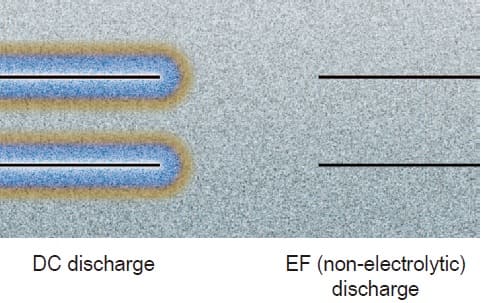

Electrolysis Free [Ef ] (AC Power Generator)

Electrolysis Free(EF) Generator System is a new design provided by the EXCETEK for the best generating cutting performance.

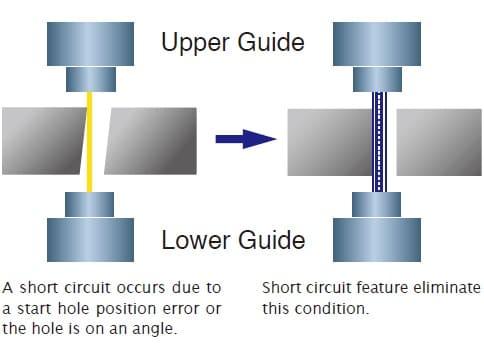

Short Circuit Solution

During the misalignment of threading, short circuit takes place after completion of threading. So, A special discharge circuit is provided to eliminate the short circuit condition and improve machining efficiency.

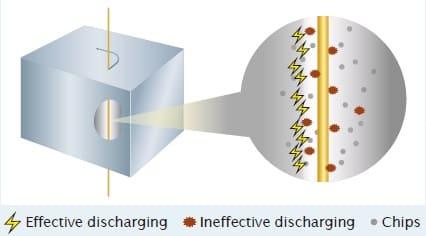

RTS (Real Time Sparking)

Short response time provides feedback of ineffective discharges and adjusts the condition for improving the cutting efficiency.

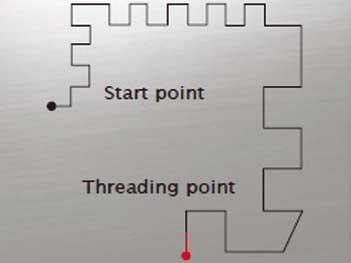

Threading at break point

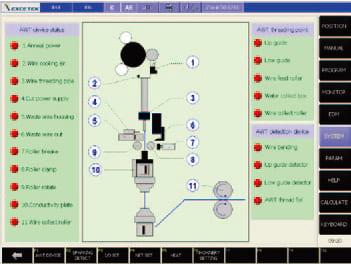

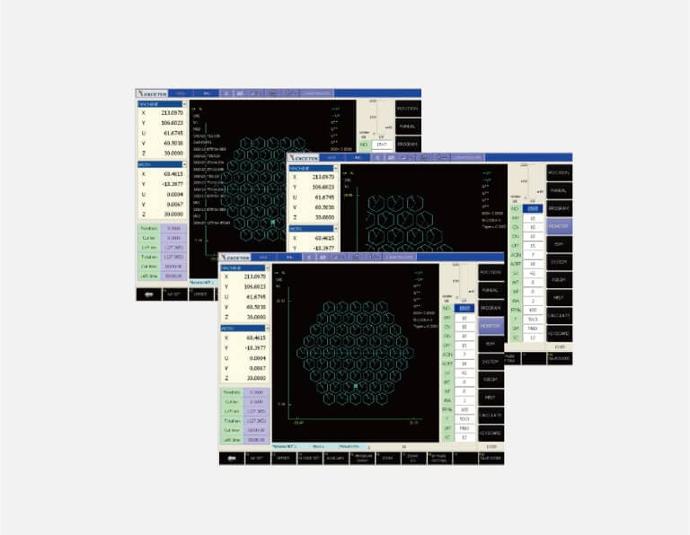

AWT Monitor

AWT Result Monitor

Annealing wire threading

Threading Wire At Break Point:

Annealing function is used to improve the wire straightness while threading. The wire can be threaded at the break point during machining, with virtually 100% reliability and without the need of return to the start hole.

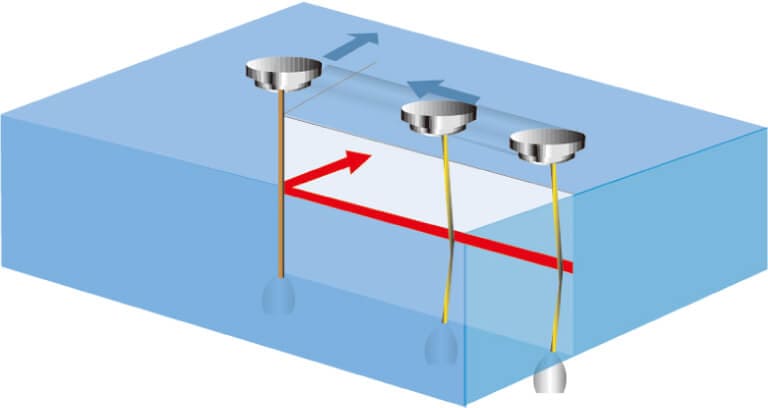

Submerged Wire Threading:

Wire Threading can also be executed easily during submerged machining where it is not necessary to drain water or refill the work tank.

Multi-Hole Machining Function:

In continuous machining function, when the machine fails to rethread at multi-hole machining, the system will skip current hole and continue to next hole. The location of the skipped hole is automatically recorded in the data memory and it recalls the skipped hole later during the completion of the cut.

Threading with water jet: in the case of tall work pieces, water jet can be used to enhance the wire threading operation.

Reliable Auto Wire Threading system

The EXCETEK AWT is very useful design that provides continuous unmanned operation day and night, its outstanding feature by comparison to other competitors is threading at the point of wire breakage.

Water jet function enables the machine to thread a thickness of 500 mm.

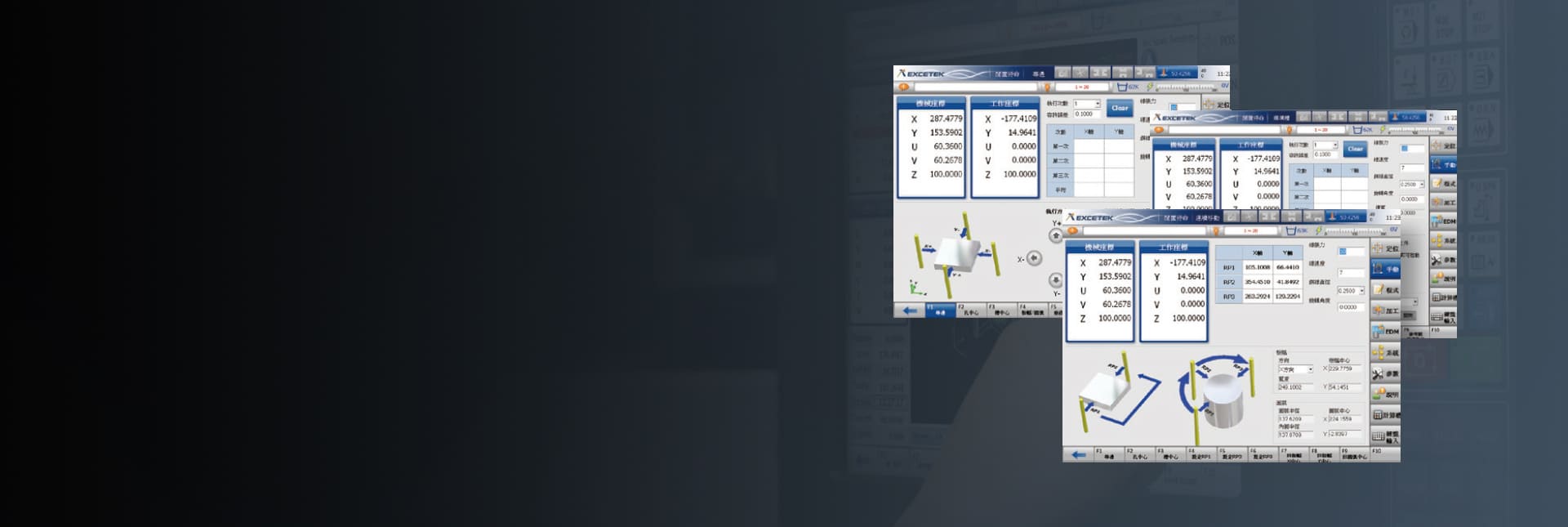

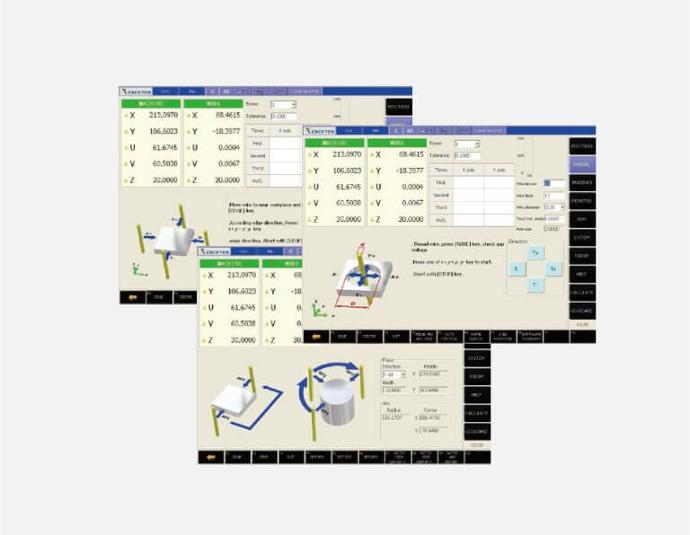

Graphical Interface

EXCETEK V Series - The control of W6 takes care of users.

- CNC Device: Industrial PC

- CPU: Pentium 64-bit 64 bits high speed CPU

- Operation Interface: 15'' LCD touch screen,Keyboard, Mouse

- Input Interface: LAN, USB driver, Floppy, RS-232

- Memory capacity: 512 MB CF card

- Min. command unit: 0.0001mm

- Max. programmable dimension: ±9999.9999mm

- Unit: Metric / Inch Switch able

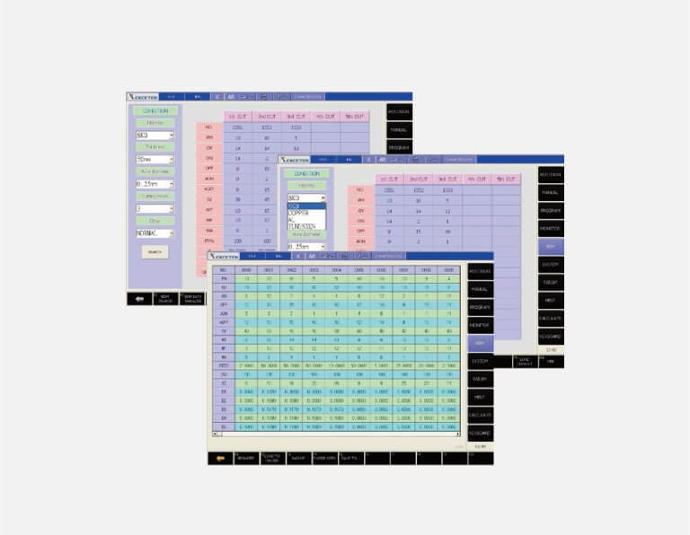

Intelligent Machining mode

Watchdog during machining

Well considered in NC settings

Database cutting technologies

Icons assistant to user

Parameters & Maintenance information

Remote Control (Standard Accessory)

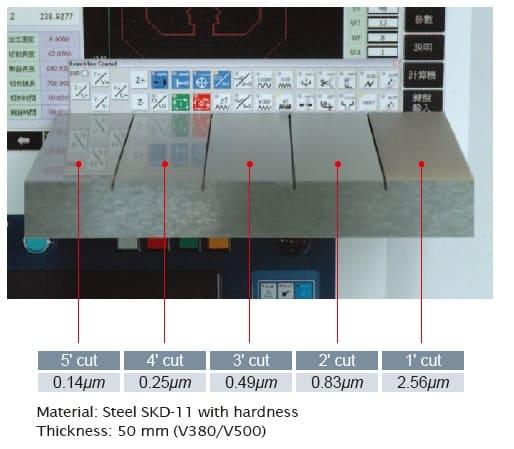

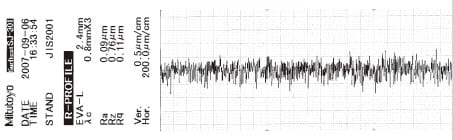

Super Finish Circuit (option)

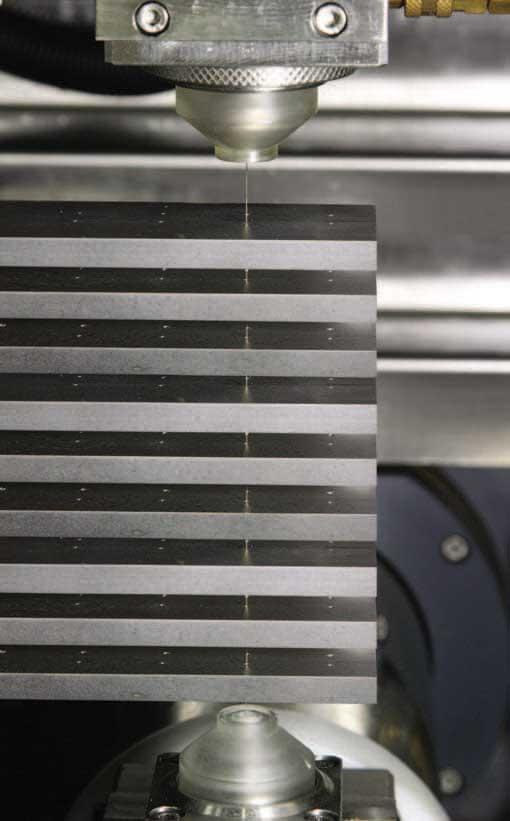

High frequency technologies of surface finish are used to generate a roughness less than Ra 0.2 micrometer which can be obtained in single cut with 4 skims.

Steel SKD-11, thickness 30mm

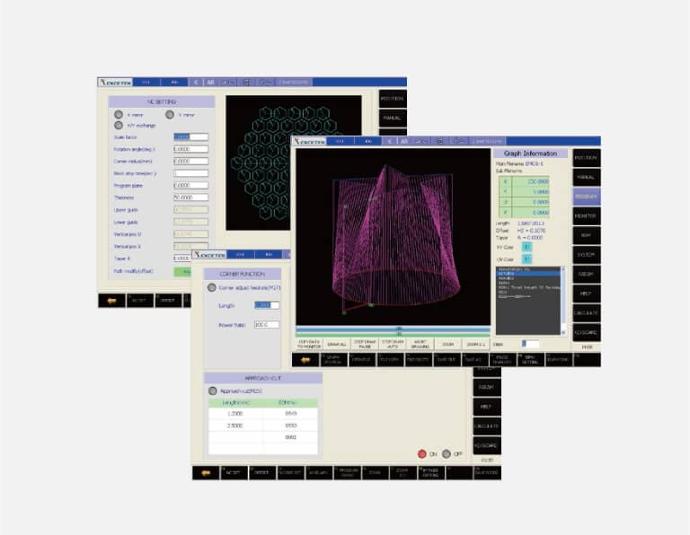

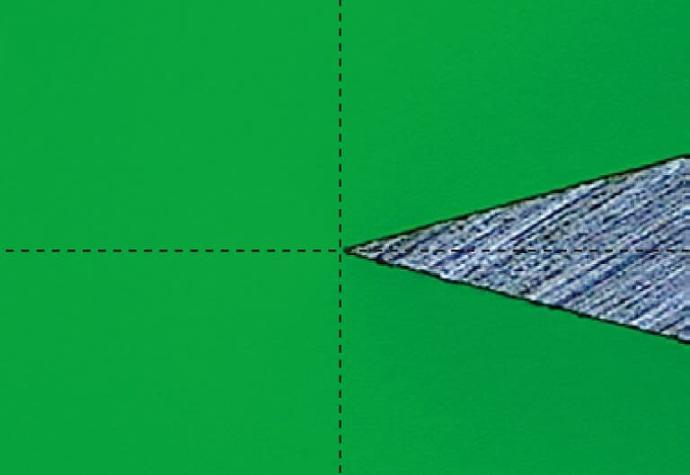

The corner control

Machining at Corner control parameter helps to control the machining speed and inhibiting of the wire twisting conditions. Hence it reduces the cornered 'washout' which ensures the machining accuracy and molding compatibility. And effectively improve machining quality and speed.

Corner angle 30° / Zoom-in x 100

Corner angle 60° / Zoom-in x 100

Corner angle 90° / Zoom-in x 100

Accessory

Standard Accessories

Ion exchange resin x 10L

Paper filter x 2 pcs

Diamond guide x 2 pcs

Upper and lower flushing nozzle x 2 sets

Energizing plates x 2 pcs

Brass wire x 1 spool

Clamping tool x 1 set

Vertical alignment jig x 1 set

Options

XY axis linear scale

W-Axis

Clamping Beam

Jumbo Feeder L-50A

AWT

Double Door

AVR 15KVA

Transformer 15KVA

Short Message Service (SMS)

Signal Tower

Remote Monitor System

Super Finish Circuit